Industrial gearboxes can be ordinarily utilized in our everyday existence. Its sorts are different. Various classes have their attributes. The motivation behind industrial gearboxes is to send movement and force starting with one shaft then onto the next. That transmission needs to happen with a steady proportion, the most reduced potential unsettling influences and the conceivable effectiveness. As to one sort of industrial gearbox which is known as the round and hollow industrial gearboxes, it is more clear that the involute profile gives a consistent proportion and is heartless toward focus distance displacement. The producing rule of an involute is gotten from a straight rack with straight tooth profile. A specific gearbox, moving in the rack with consistent focus distance to the rack, requires involute flank surfaces. A molding instrument with the state of a rack can machine a gearbox with involute flank structure.

To comprehend the slope gearbox tooth calculation, you could initially notice the instance of straight angle industrial gearboxes. On the off chance that the creating rack used to determine the round and hollow gearbox involute is bowed in a level plane into a roundabout shape, it will bring about a crown gearbox which is utilized to determine the flank type of slant pinion and gearbox. On account of straight slope industrial gearboxes, the crown gearbox or creating gearbox can be put between the pinion and gearbox gathering. Its middle is found precisely at the convergence point of the pinion and gearbox shafts. It is feasible to utilize a slant creating gearbox that is indistinguishable from the ring gearbox. The pinion is all things considered created by moving with the slant producing gearbox, and the gearbox is made essentially by plunging the shaper to full profundity without rolling. With a winding slant gearbox set, the contact lines are slanted comparative with the pitch line direction. Dissimilar to the contact lines of the straight slant gearbox set, the contact lines of gearbox repairs near me set have various lengths.

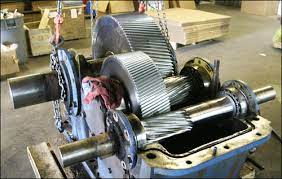

The contact lines among gearbox are indistinguishable from the contact lines between shaper sharp edges and pinion flanks. Industrial gearboxes are machines that cause force or movement in mechanical frameworks appended to them. These are by and large tooth molded pivoting machines that structure a couple with at least one tooth formed pieces of a mechanical framework. Such a game plan which gives movement to entire framework is named as Gearbox. The primary goals are to change over mechanical energy into some type of movement and to adjust the speed and course of that movement. On the off chance that two unique industrial gearboxes of various sizes are in transmission, the modest gearbox will move more quickly than the greater one. A transmission is like a cross belted pulley movement with two wheels. However if there should arise an occurrence of industrial gearboxes we enjoy a benefit – industrial gearboxes do not slip because of their tooth molded structure. Industrial gearboxes are apparatus in the machines as a whole and machines that need movement to play out some activity.